Mentis Medvante is a renowned company that generates oxygen plant with the latest technology. Our manufacturing and fabricating of oxygen generation plant is done in compliance with the nicest manufacturing techniques. The materials that we used are also best in terms of quality.

Mentis Medvante Oxygen Plant in India is successfully established, leading at various Hospitals in India and running towards our mission.

Medical grade oxygen produced by our oxygen plant is provided to ICU’s and OT’s. Not only this, in fact it is also delivered during anesthesia as an alternative for nitrous oxide to lower the high concentration of oxygen exposure. Advanced hospitals are achieving motives of medical oxygen generator using a onsite Medical oxygen gas generator along with a back-up of cylinders. With the passage of time, hospitals globally are realizing that on-site medical oxygen generator provides a highly credible and monetary solution. For their oxygen requirements to their patients onsite Oxygen plant is the only solution. Because there will be no worry about the charges of purchasing, receiving, and controlling your hospital’s oxygen supply. Hospitals can run out of medical oxygen using cylinders, if there is no proper maintenance done by the operator. As a prime running medical oxygen generator manufacturer, Mentis Medvante delivers accurate procedures for medical oxygen generation, storage, and allotment. Our professional team look after of each and everything from design, manufacture to stock, erection and commissioning of oxygen gas plants.

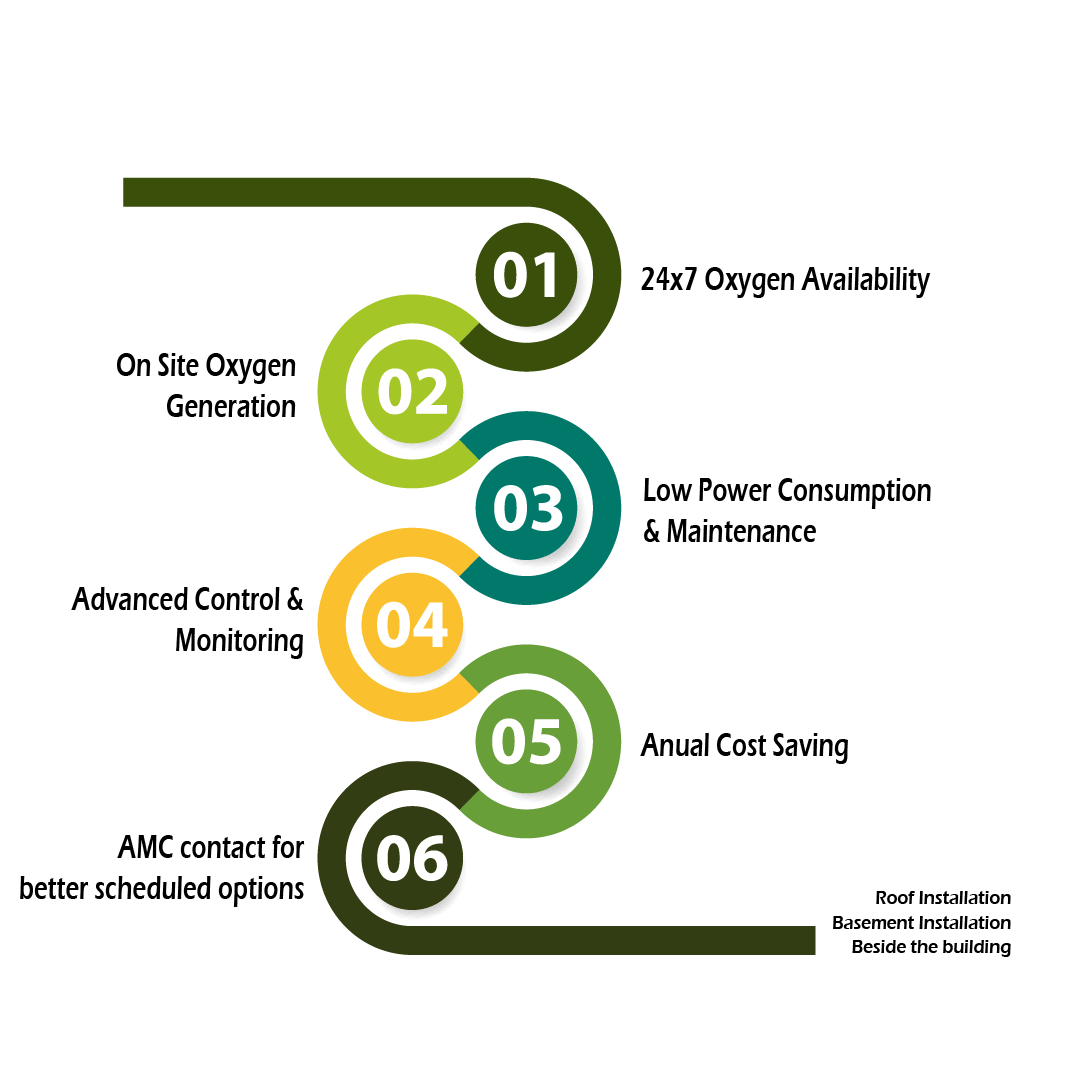

Why Mentis Medvante plant?

Here are the Advantages of Mentis Medvante Oxygen Systems

This is suitable for an on-site hospital unit, because it is safe to use and covers less area.

The system operates by using adsorbents to separate air components. The main equipment that are required in PSA is a compressor, an activated alumina bed, two adsorption columns, and a storage tank.

1. Pressure Swing Adsorption

This is suitable for an on-site hospital unit, because it is safe to use and covers less area.

The system operates by using adsorbents to separate air components. The main equipment that are required in PSA is a compressor, an activated alumina bed, two adsorption columns, and a storage tank.

Here are their uses:

* Compressor plays a vital role to supply the required volume of atmospheric air to produce the desired purity and output flow rate of oxygen.

* Activated alumina bed is essential to eliminate water vapor and impurities such as carbon dioxide and carbon monoxide.

* Two adsorption columns are used to enable for a semi-continuous supply of product.

* storage tank helps for product storage for later use.

2.Fixed Bed Column Design

Zeolite layer in the section pre-compressed with both stainless steel metal screens and springs. This design provides and there is no turbulence separation in the zeolite layer. That design conserves to zeolite particles from air turbulence. Zeolite particles can not be shifted under pressure or velocity effect. Otherwise, Zeolite particles would be destroyed and be smashed into dust. So you don’t need any extra zeolite in the future with our fixed-bed column design

3.Improved Energy Saving

Mentis Medvante units only consume 0.7 kWh power to produce 1 Nm3 oxygen (93%) if you are not believing you can test other PSA manufacturer specifications about power and compressed air consumption.You will assume minimum 1.10 kWh per 1 Nm3 oxygen. That’s why they require larger compressor capacity and much extra power.

4.Advanced Control And Monitoring

Our equipment’s provide high definition touch screen control panel with the a digital screen with effective size.

* Facilitates Automatic regulation with energy-saving working mode.

* User friendly software

* Real time duration and immediate monitoring and trending curves for oxygen purity, pressure and actual oxygen consumption rate (ACR)

* 24/7 long lasting recording possibility on SD Card or USB data acquisition.

* Preventive sustenance spontaneous warnings.

* Remote alarm options via SMS (mobile phone)*

* Historical logging of all alarms.

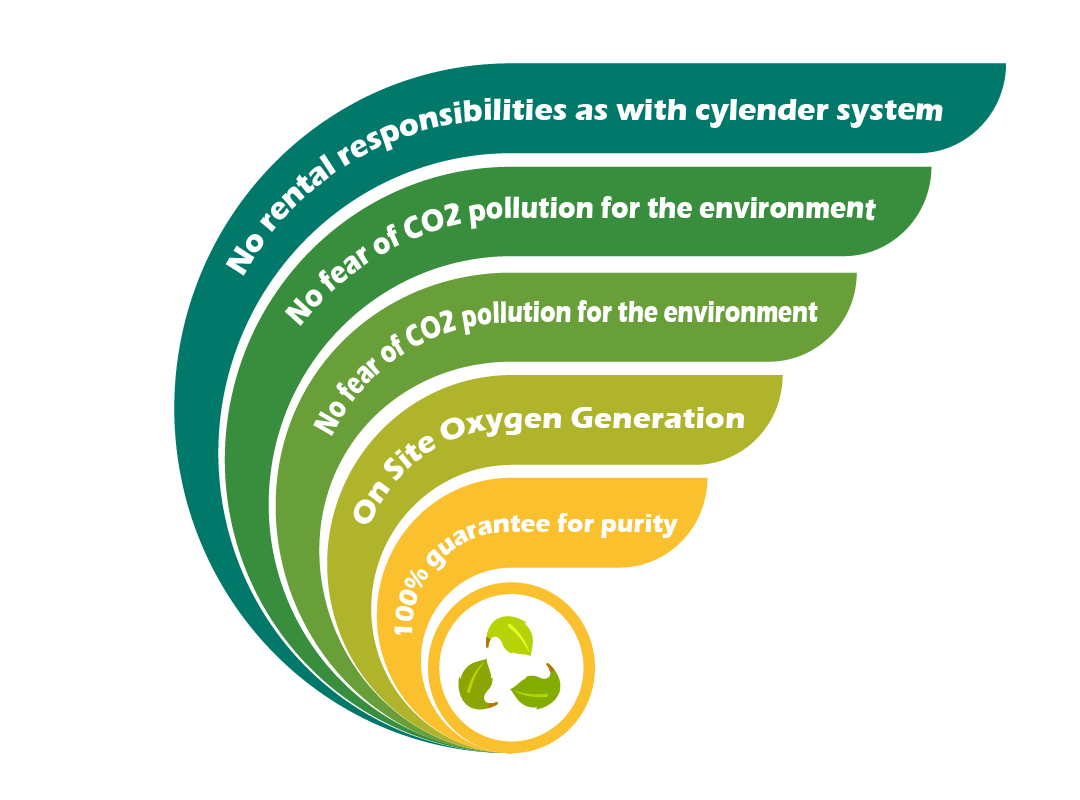

So ,the Windfalls in a nutshell are:

* On Site Oxygen Generation

* Provide best equipments at Reasonable costs

*Smart and credible technology

*100% guarantee for purity

*No rental responsibilities as with bottles/bundles and tank systems

*No fear of CO2 pollution for the environment

*Familiar to use.

*No danger of explosion

*In-house arrangement and production