If you're in search for Best Medical Oxygen Plant Supplier for Hospital?

Then, you are absolutely at the right place. Medvante is here!

Medvante is a well-established and leading Medical Oxygen Plant Supplier for Hospitals. We are a renowned Medical oxygen generator manufacturer and proud to achieve huge milestone in just few years with our ground breaking technology. The components used in our systems are sourced from best manufacturers around the world and finally designed in our proprietary technology S-PSA. The product gas I.e oxygen is regularly monitored with Gold standard zirconium sensor, strictly adhering to global pharmacopeia standards. Our Systems are capable of producing both 95%±1% and 99± 0.5% oxygen purity levels. This make us different and dependable from others

Why Us.

Medavante never compromises when it comes to the matter of quality. We partnered with Mentis Engineering, Turkey for our gas generators systems. Mentis is world renowned engineering driven organization having more than 15 years proven background as a technology solution provider and accumulative team experience of more than 300 projects in the field of PSA technology oxygen and nitrogen generator systems. Some point that’s makes us different from others.

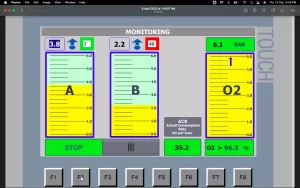

Advanced Control And Monitoring

- Actual Consumption rate of hospital in m3/hr ( Industry’s First)

- Trends and Event Logs of Purity, Pressure & Consumption rate parameters

Remote Monitoring (optional) Available

Most Energy Efficient PSA

Consumes only 0.7 Kw for 1 m3 of Oxygen compared to other PSA Systems.

Eg SPSA-40 produces 165 ‘J’ Type cylinders using just 37 KW Compressor.

Inbuilt Desiccant Dryer

Integrated Desiccant Dryer assures dew point of -40 degree pressure at 7 barg, while other PSA companies uses Refrigerant dryer that provides +3 to +10 degree pressure dew point, Hence water and oil content is 75 percent less as compared to Refrigerant dryer

Smallest Foot Print

Integrated Dryer in the system with excellent design assure smallest footprint in the Industry.

Gold Standard Zirconium Oxygen Sensor

Purity of Product Gas i.e Oxygen is continuously monitored by Zirconium Sensor sourced from SST Sensing UK assures quality round the clock.

8 years warrantee on Molecular Sieves

With our design we assure 8 years warranty on the Molecular Sieves used in our system, Please check with other PSAs..

Our Products

Produce oxygen gas from 3 to 1000 Nm3 per hour at up to (95%±1%) oxygen concentration. (with the purity of 99% High Purity Oxygen Generators are available if required)

Are medical oxygen generators credible?

One of the biggest advantage of Oxygen generator is that you get oxygen all 365-days. Whereas there may be interruptions in market Oxygen supply because of absence of cylinders or delay in delivery of cylinders due to transportation delays. PSA is a best proven technology and thousands of such Medical Oxygen generators are being used worldwide in hospitals. These generate oxygen with safe purity and pressure of 5 kg/cm2g for supplying Oxygen through pipe line directly to beds.

How much space is needed for launching a medical oxygen generator?

If you are thinking about establishing a medical oxygen generator you should have at least 20-25 lakh rupees in your budget. In terms of space, then 100 square feet space is needed for launching a medical oxygen generator.

When will I recover my investment cost?

The Medical Oxygen plant setup investment in India is possible to recover in less than 2- year time which is an impressive financial proposition for any hospital. You not only save money on the cost of oxygen, you also benefit from reduced man power cost needed for cylinders handling.

Is producing oxygen on premises less expensive than purchasing cylinders?

Cylinder Oxygen average costs Rs. 300 per cylinder of 7 m3 capacity. Whereas in oxygen generator gas expenditure is only Rs. 60-65 per cylinder. So you will save your huge money.. For Oxygen cylinders handling, you need to keep 3-workers in 8 hours shift, costing Rs. 30,000 per month, Also Under-filling is an extra concern.

What are the safety concerns of PSA Oxygen Plant ?

Operating Pressure of PSA Oxygen Plant is Max 6 Bar on the other hand Cylinders Pressure Range is 120-150 Bar and Liquid Oxygen Container needs NOC from PESO Govt of India. Hence PSA Systems are far safer than existing sources.

Medical Oxygen Generator versus Cylinders or Liquid Oxygen?

The very clear answer of this question is that ,In India Medical Oxygen plant setup investment is likely to recover in less than in the period of 2-years that is really a remarkable financial recommendation for any hospital. You will not only save your money or investment on the cost of oxygen, but will also reduced man power expenses required for cylinders handling and management.

Some friends we’ve made in the process.

MG Hospital, Jaipur

“We are happy to being a customer of Medvante India whose services are truly satisfied in effective costs. Their oxygen suppliers are completely risk free and no danger of explosion.”

Mr Yogendar Verma

Director Purchase

Sri Rama Himalayan University , SRHU Dehradun

We have Installed High Purity 99% Machine of Capacity 130 m3/hr, Very Satisfied with the performance and after sales service``

Mr Girish Uniyal

HOD Engineering Department

Amandeep Group of Hospitals Amritsar Punjab Model SPSA40

“We are completely satisfied with the outstanding services provided by Medvante India. The team is highly trained and experienced which helps us on every step.”

Dr. Shahbaz Singh

MD

Madhubani Medical College , Bihar Model SPSA30

“We are so glad that we decided to work with Medvante . The experience with Medvante was high quality materials used in their systems. The team is highly trained and experienced that guide us on every step.”

Mr Tausif Ahmed

Director

Florem Hospital, Amritsar

“We are elated that we opted to work with Medvante. Their Oxygen Plant produces the oxygen with purity of 95%±1% in affordable price. The team is highly trained and experienced, and they will guide us through every step.”

Dr. Josan

Director

Installation

Working hours were spent